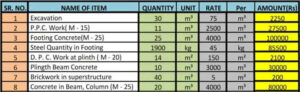

Excavator productivity per hour in m3 refers to the volume of material an excavator can dig, move, and place in cubic meters within one working hour. This metric is a reflection of an excavator’s efficiency and performance. It depends on various factors, including the machine’s size, type, attachments, operator skill, ground conditions, and the nature of the material being excavated.

Excavator Productivity per Hour in m3 according to model

| Excavator Model | Size (tons) | Average Productivity (m3/hour) |

|---|---|---|

| Caterpillar 320 | 20 | 90 |

| Komatsu PC200 | 20 | 85 |

| Volvo EC220 | 22 | 88 |

| Hitachi ZX210 | 21 | 92 |

| JCB JS220 | 22 | 86 |

Excavator Productivity per Hour in m3 according to Excavator Type

| Excavator Type | Weight Range (tons) | Productivity Range (m3/hour) |

|---|---|---|

| Small Excavators | 1 to 5 | 10 to 20 |

| Medium Excavators | 6 to 10 | 20 to 40 |

| Large Excavators | 11 to 50 | 40 to 100 |

| Heavy-Duty Excavators | Over 50 | 100 |

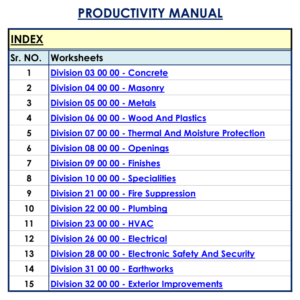

Interested in other Earthmoving equipment productivity rates?

Visit this article: Standard Productivity of Construction Machinery PDF

_________________________________________________________

Download the Standard Productivity of Construction Machinery PDF

_________________________________________________________

Factors Influencing Excavator Productivity

To achieve optimal productivity, it’s essential to consider several factors:

1. Excavator Type and Size

The choice of excavator type and size directly affects productivity. Larger excavators with higher horsepower can move larger quantities of material, making them suitable for larger projects, while smaller excavators are better for confined spaces.

2. Operator Skill and Training

Well-trained operators can significantly impact productivity. Experienced operators understand the machine’s capabilities, work more efficiently, and can handle various tasks with precision.

3. Attachment Selection

Attachments like buckets, rippers, and hydraulic hammers are essential for specific tasks. Choosing the right attachment for the job optimizes productivity and minimizes downtime.

4. Ground Conditions

Soil type, moisture content, and terrain influence productivity. Rocky or uneven terrain may slow down excavation, while softer soil could be easier to dig.

5. Material Density and Type

The type of material being excavated and its density affect how quickly the excavator can move it. Loose soil may require less effort than densely packed material.

Strategies for Maximizing Productivity

Boosting excavator productivity per hour in m3 requires a combination of strategic planning and operational excellence:

1. Proper Equipment Maintenance

Regular maintenance ensures the excavator operates at its peak performance. Lubrication, hydraulic fluid checks, and routine inspections prevent breakdowns and maintain efficiency.

2. Operator Training and Skill Enhancement

Investing in operator training and skill development leads to better productivity. Operators should be familiar with the machine’s controls, features, and best practices.

3. Efficient Work Planning

Effective project planning and task sequencing minimize idle time. Operators should have a clear understanding of their tasks to avoid unnecessary delays.

4. Attachment Selection and Optimization

Choose attachments that match the task requirements. Quick attachment changes and adjustments improve overall efficiency.

5. Real-time Monitoring and Data Analysis

Implement telematics and monitoring systems to track machine performance. Analyzing data helps identify areas for improvement and enhances decision-making.

FAQs about Excavator Productivity per Hour in m3

How can I calculate excavator productivity per hour in m3?

To calculate excavator productivity, measure the volume of material moved in cubic meters within an hour. Divide the volume by the number of hours worked.

What is a good excavator productivity rate?

An average excavator can move around 50 to 100 m3 per hour. However, rates can vary based on factors like machine size, operator skill, and ground conditions.

Can attachments affect excavator productivity?

Yes, the right attachments can enhance productivity. Using buckets, thumbs, or couplers designed for specific tasks increases efficiency.

How can I improve operator performance?

Regular training, operator feedback, and adopting best practices can improve operator efficiency and productivity.

Is technology beneficial for excavator productivity?

Absolutely. Telematics, GPS systems, and monitoring tools provide real-time data, helping operators make informed decisions and optimize performance.

What safety measures should be considered?

Safety is paramount. Operators should follow all safety protocols and wear appropriate personal protective equipment to prevent accidents.

Conclusion

In the realm of construction, excavator productivity per hour in m3 is a vital metric that directly influences project success. By considering factors such as machine type, operator skill, and ground conditions, and implementing strategies like efficient planning and attachment optimization, professionals can significantly enhance excavator productivity. The result? Smoother projects, improved timelines, and better cost-effectiveness.

So, whether you’re a seasoned professional or just starting in the construction industry, remember that excavator productivity per hour in m3 is the key to unlocking success in your projects.