Scaffolding is one of the most important aspects of construction projects, and efficiency in this area can significantly impact your project’s success. In this article, we will explore the various factors and methods involved in calculating scaffolding productivity to ensure your construction endeavors run smoothly.

Table of Contents

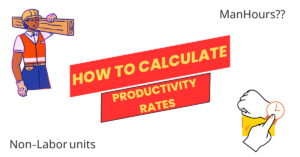

How do you calculate scaffolding productivity?

Productivity in General varies from one country to another, from one project to another, and from one worker to another.

We provide norms and standard labor productivity rates for scaffolding works that you can use as a guide while calculating your project resources and duration.

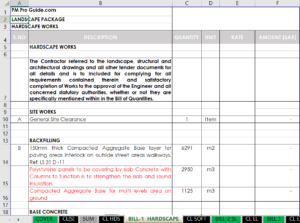

| Task / Description | Slow | Ave | Fast | Units |

|---|---|---|---|---|

| Metal KwikStage, 5 Boards with 2m lifts | 11.1 | 11.9 | 12.5 | m run/hr |

| Metal KwikStage, 5 Boards with 3m lifts | 9.1 | 10.0 | 10.5 | m run/hr |

| Metal KwikStage, House Scaffold with 3 lifts | 2.8 | 3.2 | 3.8 | m run/hr |

| Metal Tube and Fittings, 5-6 Boards wide | 3.2 | 3.7 | 4.6 | m run/hr |

| Tube and Fitting Platforms, 50-250m3 | 10.6 | 12.5 | 18.5 | m3/hr |

| Tube and Fitting Platforms, 250-1000m3 | 18.5 | 22.5 | 24.5 | m3/hr |

| Tube and Fitting Platforms, over 1000m3 | 24.5 | 30.0 | 33.5 | m3/hr |

| Tube and Fitting Platforms, striking | – | 200.0 | – | % x erect |

What is the unit rate of scaffolding?

This depends on the material used, some engineers use Meter/time. Example: 20 m/hr. That’s when you use metal Kwikstage.

Other engineers use volume over time. Example: 20 m3/hr. That’s when you use Tubes and Fitting Platforms.

How do you calculate scaffolding in m3?

A- How to Calculate Ringlock Scaffolding in m3

1- Ringlock Scaffold Sizes

1)Wall Length: 6.2m

2)Wall height: 7m

3)Ringlock bay length: 2.07m

4)Ringlock bay width: 0.73m

5)Ringlock platform width: 320mm

6)Need guardrails for each deck

7)Lifting height is 2m

Ringlock scaffolding material quantity

1)7m height scaffold needs 2*3m ringlock standards and 1*1.0m ringlock standards

2) One layer ringlock standards quantity is (3+1)*2=6pcs, Two layers of 3.0m standards quantity is (3+1)*2*2=16 pcs

3)One layer of 1.0m ringlock standard quantity is (3+1)*2=8 pcs

4)One layer 6.2m bay length needs three 2.07m ringlock ledgers.

5)One layer 2.07m ringlock ledger quantity is 3*2=6 pcs

6)7m height (three lifting height) need 4 layers of ledgers, 2.07m ledger total quantity is 6*4=24 pcs

7)Three bay length need 4 pcs of 0.73m ringlock ledgers

8)One layer 0.73m ringlock ledger quantity is 4 pcs

9)7m height scaffold is 3 lifting height and 4 layers of 0.73m ledgers. 0.73m ledger total quantity is 4*4=16 pcs

10)One ringlock decks set 2 pcs of platforms. One layer 6.2m bay length platform quantity is 2*3=6pcs

11) Three (layer) decks platform quantity is 6*3=18pcs

B- How to Calculate Cuplock Scaffold in m3

1- Cuplock Scaffold Size

Height: 7.5m (2*3m+1*1.5m=7.5m)

Width: 0.6m (For 2*230mm planks)

Length: 6m (3*2.0m=6m)

Scaffold Decks: 3 Layers

2- Cuplock Scaffolding Material Quantity Calculation

3m Cuplock Standards Quantity: (3+1)*2*2 =16 pcs

1.5m Cuplock Standards Quantity: (3+1)*2*1=8 pcs

Base Jack Quantity: (3+1)*2 =8 pcs

2.0m Cuplock Ledger Quantity: 4*3*2=24 pcs

2.0m Ledger for Handrail Quantity: (4-1)*3*2*2=36 pcs

0.6m Ledger Quantity: 4*(3+1)*1=16 pcs

0.6m Ledger for Handrail Quantity: (4-1)*2*2=12 pcs

230mm Width Steel Plank Quantity: (4-1)*3*2 =18 pcs

2.0m Toe Board Quantity: (4-1)*3*2=18 pcs

0.6m Toe Board Quantity: (4-1)*1*2=6 pcs

C- How to Calculate Kwikstage Scaffolding in m3

1- Kwikstage Scaffold Size:

- Height: 7.5m (2*3m+1*1.5m)

- Width: 0.76m (For 3*230mm Plank)

- Length: 7.31m (3*2.44m)

- Scaffold Decks: 3 Layers

2- Kwikstage Scaffolding Material Calculation:

- Base Jack Quantity: (3+1)*2=8 pcs

- 3m Kwikstage Standards Quantity: (3+1)*2*2 = 16 pcs

- 1.5m Kwikstage Standard Quantity: (3+1)*2*1=8 pcs

- 2.44m Kwikstage Ledger Quantity: 4*3*2=24 pcs

- 2.44m Ledger for Handrails: (4-1)*3*3*2=36 pcs

- 0.76m Kwikstage Transoms Quantity(For Plank): (4-1)*(3+1)*1=12 pcs

- 0.76m Kwikstage Ledger Quantity: 1*(3+1)*1=4 pcs

- 0.76m Kwikstage Ledger(For Handrails) Quantity: (4-1)*(3+1)*1=12 pcs

- 2.44m Kwikstage Planks Quantity: (4-1)*3*3=27 pcs

- 2.44m Kwikstage Toe Board Quantity: (4-1)*3*2=18 pcs

- 0.76m Toe Board Quantity: (4-1)*1*2=6 pcs

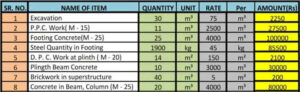

D- How to Calculate Scaffold Tube and Clamp in m3

Tube Clamp Scaffold Size

- Height: 7.5m (1*6m+1*1.5m)

- Width: 0.73m

- Length: 6m (2*3.0m)

- Scaffold Decks: 3 Layers (225*38mm Boards)

Tube Clamp Scaffolding Quantity Calculation:

- Base Plate Quantity: (3+1)*2 = 8 pcs

- 6.0m Scaffolding Pipes Quantity: (3+1)*2*1=8 pcs

- 1.5m Scaffolding Pipes Quantity:(3+1)*2*1=8 pcs

- 3.5m Scaffolding Pipes(Form 3.0m Ledger) Quantity: (4*2-2)*3*2*2=120 pcs

- 1.0m Scaffolding Pipes (For 0.73m Ledger) Quantity: (4*3-2)*1*2=20 pcs

- 2.0m Plank Quantity: (4-1)*3*3=27 pcs

Factors that affect Scaffolding Productivity

Scaffolding productivity is a multifaceted concept that involves several key components. To calculate it effectively, consider the following factors:

1. Scaffolding Materials Inventory

Maintaining a comprehensive inventory of scaffolding materials is essential. Ensure you have sufficient materials, including pipes, couplers, planks, and safety gear, to avoid downtime.

2. Work Crew Management

Efficiently managing your work crew is crucial. Assign roles and responsibilities, set clear expectations, and provide adequate training to maximize productivity.

3. Site Preparation

Before erecting scaffolding, ensure the worksite is well-prepared. Clear any debris, level the ground, and create a safe environment for scaffolding installation.

4. Scaffolding Design and Layout

The design and layout of scaffolding should be optimized for the specific project requirements. A well-designed scaffolding structure can significantly enhance productivity.

5. Safety Measures

Prioritize safety at all times. Ensure your crew follows safety protocols to prevent accidents and minimize downtime due to injuries.

6. Monitoring and Tracking

Implement a robust monitoring system to track the progress of scaffolding activities. Regularly assess productivity and make adjustments as needed.

7. Time Management

Efficient time management is key to optimizing productivity. Create a realistic schedule and adhere to it to meet project deadlines.

8. Equipment Maintenance

Regularly inspect and maintain scaffolding equipment to prevent breakdowns that can disrupt productivity.

9. Quality Control

Maintain strict quality control standards to ensure that the scaffolding is safe and meets all regulatory requirements.

10. Communication

Effective communication among team members is essential. Encourage open and clear communication channels to address issues promptly.

11. Weather Considerations

Weather can impact scaffolding productivity. Have contingency plans in place for adverse weather conditions.

12. Scaffolding Dismantling

Efficiently dismantle scaffolding once the project is complete to minimize downtime.

13. Training and Development

Invest in ongoing training and development for your scaffolding crew to enhance their skills and efficiency.

14. Technology Integration

Explore the use of technology, such as scaffolding design software and project management tools, to streamline processes.

15. Cost Analysis

Regularly analyze the costs associated with scaffolding to identify areas where savings can be made without compromising safety.

16. Compliance with Regulations

Stay up-to-date with industry regulations and ensure your scaffolding practices align with legal requirements.

17. Client Feedback

Seek client feedback and incorporate their input into your scaffolding processes for continuous improvement.

18. Environmental Sustainability

Consider sustainable scaffolding practices to minimize the environmental impact of your construction projects.

19. Case Studies

Explore real-world case studies of successful scaffolding projects for valuable insights and inspiration.

20. Industry Trends

Stay informed about the latest trends and innovations in scaffolding technology and practices.

Frequently Asked Questions (FAQs)

Q: Can you provide some tips for optimizing scaffolding crew management? A: Efficient crew management involves clear role assignments, ongoing training, and effective communication to maximize productivity.

Q: What role does technology play in scaffolding productivity? A: Technology can streamline scaffolding design, project management, and monitoring, leading to increased efficiency.

Q: How can I ensure the safety of my scaffolding crew? A: Prioritize safety protocols, provide proper training, and regularly inspect equipment to minimize accidents.

Q: Are there any sustainable scaffolding practices? A: Yes, you can use eco-friendly materials and design scaffolding systems with minimal environmental impact.

Q: What are the key benefits of optimizing scaffolding productivity? A: Optimizing scaffolding productivity leads to cost savings, faster project completion, and improved safety.

Q: How do I stay updated with the latest scaffolding trends? A: Keep an eye on industry publications, attend conferences, and network with experts to stay informed.

Conclusion

Optimizing scaffolding productivity is essential for the success of any construction project. By implementing the strategies and considerations outlined in this guide, you can enhance efficiency, reduce costs, and ensure the safety of your scaffolding crew. Remember, a well-organized and productive scaffolding process is a cornerstone of successful construction.

Other resources that may help

Scaffolding by Methvin

How to Calculate Scaffolding Material Quantity