In this article, you’ll learn how to calculate productivity rates for literally anything, in easy steps.

Productivity rates are one of the main concepts that may lead your project to success (if they’re realistic), or could drive your project to misleading dates and delays.

Building a time schedule is not an easy task, but one of the most important steps in creating time schedules for any project is calculating the number of man hours needed to complete a certain activity.

What are manhours?

Manhours or Man-Hrs or manhrs, are the total number of hours, that the worker/labor needs to finish a certain task in a certain amount of time.

So if task A needs 10 mahrs to be done, that means it needs one worker that will work for 10 hours to finish the task.

Or 2 workers, each of them works for 5 hours. Or 10 workers, each of them works for 1 hour.

Basically, we use manhours to estimate the level of effort that a certain task or activity needs to be finished.

In some projects, they use those manhours as a KPI to check which part of the project will need more effort, and also to know how much of work we really finished.

What are productivity rates?

Productivity rates are numbers that are used to indicate how fast a task can be finished. It’s important for all engineers to know how to calculate productivity rates manually.

It’s as simple as that. If the carpenter rate is 1 table per day, that means the carpenter can do one table per day.

That also means, that if we need to create one table, that will take one day for a carpenter. Or 2 carpenters for half a day, and so on.

Another example:

If we have a concrete slab that we want to cast in the site in 5 hours, this slab is 100 m3 of concrete. We need to cast this slab using a concrete pump. What should we do if we want to know, how many concrete pumps do we need to complete this task?

Here comes the importance of productivity rates, the missing piece in this problem is how many m3 that the pump can cast in an hour.

- If the pump rate is 1m3/hr, so we need 20 pumps to work at the same time. 20 pumps, each one places 1 m3 in each hour, that means 20 m3 in the hour. They will work for 5 hours, so 20*5=100 m3.

That’s how we can know how many pumps that we need to get ready for this task. And that’s what we call: Resources Allocation.

What is Resource Allocation?

Resources allocation is simply calculating the needed resources for completing a certain task, and making sure you can access them to get your task done.

Calculating how many resources are needed is necessary for any project manager, each site engineer or project manager needs to know how many workers he needs the next week for the lookahead tasks.

Each site engineer needs to know how much equipment he will need to finish his project. And for how long does he need them?

That’s called “Optimization”, resources optimization is making sure that you have the optimum number of resources for the optimum amount of time. And the starting point for that is knowing how to calculate productivity rates.

By resource optimization, you make sure that you finish your project on time and on budget.

How to calculate Productivity Rates?

Productivity rates are a combination of two factors, quantity and time. So, we divide a quantity over time, or the time over quantity, and voila, you have a productivity rate.

To make it easier, let’s break it down into steps.

- Define the quantity of the work and the unit.

Start with defining what is the unit of the quantity of this task. Are we talking about concrete? so the unit should be a volume unit (m3 – Cubic Meter).

Or we’re talking about building a fence, so the unit measure will be (meter) or (Yard).

Or we’re talking about ceramic tiling, so the unit is square meters (m2).

Or maybe we’re talking about some electronic units that’ll be installed, so will use their counting as a unit (Piece). - Define the unit of time.

The second step is to choose a relevant time unit, so if the task takes less than a day, you can use (hours).

If the task is long enough you can use (days) as a unit of time. - Measure the actual work.

Define a specific time frame and measure how much quantity is done in that time frame.

For example, give the carpenter 4 hours and see how many pieces of formwork he can do in that time frame. - Do the calculations to make it simple.

If he finished 12 pieces, here we can say that his productivity is 12 pieces per 4 hours. As simple as that.

We can make it more simple by dividing both sides over 4, so the final rate can be 3 pieces per hour. (12 Piece/hr) - Different shapes of productivity.

You can also do the opposite, you can divide the time unit over the quantity. So for the previous example, we can say that it takes the carpenter 4 hours to create 12 pieces. So the rate is 1 hour per 3 pieces.

The bottom line is there is no rule here, you can divide the time over the quantity or do the opposite. As long as the rate is understandable, you’re good to go.

How to calculate Manhours?

Now that we know what are the rates and how to calculate them manually, we need to know the total manhours of a certain activity. This is also called (Non-Labor units).

From its name, manhours are hours, so they have time units. So, our target is to get how many hours.

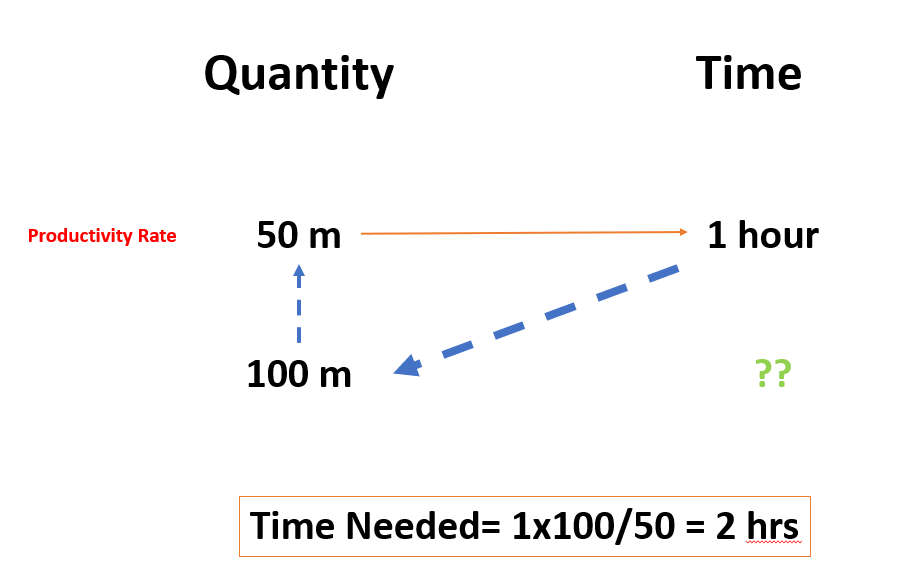

Example (1)

Productivity rate is 50 m/hr

Quantity = 100 m

Calculate the manhours.

Solution:

Mahours = 100/50 = 2 hrs

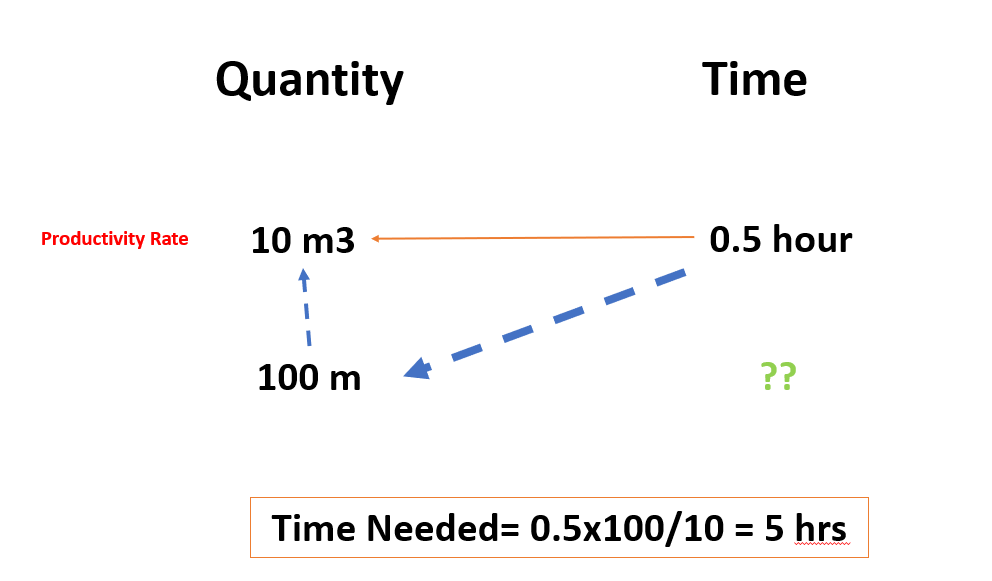

Example (2)

Production rate: 0.5 hr / 10 m2

Quantity: 100 m2

Solution:

Manhours= (100/10)*0.5 = 5 hours

It’s as simple as that

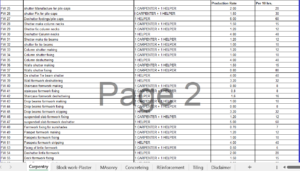

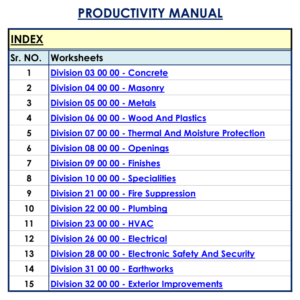

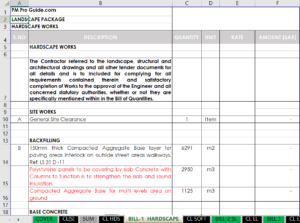

Standard Productivity Rates for Labor and Equipment

If you’re planning for a new project that you’re not familiar with its tasks and don’t know yet the right productivity rates, you may need guideline rates to start with. But remember that those rates are calculated under certain circumstances that may be different for your project.

So, I recommend calculating your own rates, and only use our rates as a starting point, then recalculate your own rates and use them later.

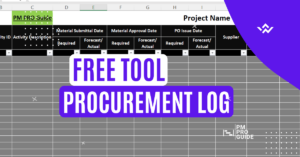

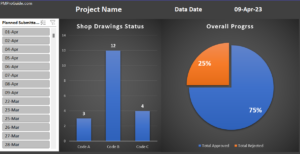

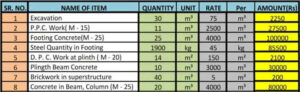

Actually, we uploaded a lot of files that have covered almost all the construction activities that you might think of.

Here are our latest Productivity Rates Files for you to download

Labour Output Per Day in Construction Excel (Updated)

Standard Productivity of Construction Machinery PDF

How do you calculate scaffolding productivity?