Table of Contents

What are long-lead items in construction?

Long-lead items are components or materials that have a long manufacturing or delivery time and therefore need to be ordered well in advance of when they are required on a construction project. These items can include specialized equipment, custom-built machinery, or materials that are in high demand and have long manufacturing lead times.

Long-lead items can have a significant impact on the construction schedule if they are not identified and ordered in a timely manner. In many cases, they may be critical to the construction process and their delay could result in overall project delays or cost overruns. As such, it is important for project managers to identify and track long-lead items as part of their project planning process.

To manage long-lead items, project managers must develop a comprehensive procurement strategy that considers the timing, quantity, and specifications of the required items. This strategy should take into account the project schedule and budget, as well as any potential risks associated with the procurement process. Effective communication with suppliers and subcontractors is also critical to ensure that long-lead items are ordered and delivered on time.

What makes a long-lead item, a long-lead item?

A long-lead item in construction is defined as a component or material that has a long manufacturing or delivery time and needs to be ordered well in advance of when it is required on a construction project. There are several factors that can contribute to an item being classified as a long-lead item:

- Customization: Items that require custom design, engineering, or fabrication often have longer lead times than off-the-shelf components. This can include items such as specialized equipment, custom-built machinery, or custom-made materials.

- Manufacturing time: Some items may have long lead times simply due to the time required for manufacturing. This can include items such as structural steel components, large-scale concrete forms, or glass curtain walls.

- High demand: Items that are in high demand or have limited availability may also have longer lead times. This can be the case for materials such as certain types of lumber, roofing materials, or specialized equipment.

- International suppliers: Items that are sourced from international suppliers may have longer lead times due to customs clearance, shipping, and other logistical factors.

It is important for project managers to identify and track long-lead items to ensure that they are ordered and delivered on time, as delays in these items can significantly impact the construction schedule. Effective management of long-lead items requires careful estimation of lead times, effective communication with suppliers and subcontractors, and a comprehensive procurement strategy.

How do long-lead items impact construction projects?

Long-lead items can have a significant impact on construction projects, as delays in the delivery of these items can cause delays in the construction schedule and ultimately result in cost overruns. The impact of long-lead items will depend on the nature of the item and the stage of the project when it is required. For example, a delay in the delivery of a critical piece of equipment may cause a delay in the construction process, whereas a delay in the delivery of non-critical materials may be less impactful.

To manage the impact of long-lead items, project managers must develop a comprehensive procurement strategy that considers the timing, quantity, and specifications of the required items. This strategy should take into account the project schedule and budget, as well as any potential risks associated with the procurement process. Effective communication with suppliers and subcontractors is also critical to ensure that long-lead items are ordered and delivered on time.

In addition to delays, long-lead items can also impact the overall cost of a construction project. If long-lead items are not identified and ordered in a timely manner, it may result in expedited shipping costs or the need for more expensive substitute items. As such, it is important for project managers to carefully manage long-lead items to ensure that they are delivered on time and within budget.

How do you manage long-lead items in construction?

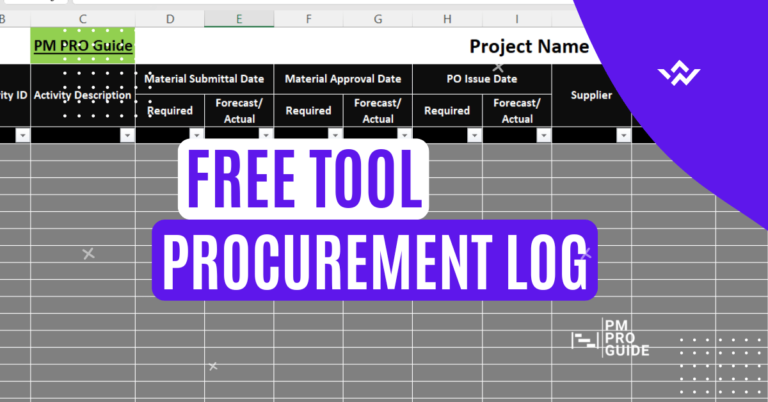

To manage long-lead items in construction, project managers must first identify and track the items that have long manufacturing or delivery times. This can be done through a comprehensive procurement strategy that considers the timing, quantity, and specifications of the required items. The strategy should take into account the project schedule and budget, as well as any potential risks associated with the procurement process.

Effective communication with suppliers and subcontractors is also critical to ensure that long-lead items are ordered and delivered on time. Project managers should establish clear expectations for delivery times and ensure that suppliers are aware of the importance of the long-lead items to the construction process.

To mitigate the impact of long-lead items on the construction schedule, project managers can consider alternative procurement strategies such as early ordering, partial shipments, or alternative materials. These strategies can help to ensure that long-lead items are delivered in a timely manner and that construction progress is not impacted.

What are some examples of long-lead items in construction?

Examples of long-lead items in construction include specialized equipment, custom-built machinery, or materials that are in high demand and have long manufacturing lead times. Some examples of long-lead items in construction include specialized equipment, custom-built machinery, or materials that are in high demand and have long manufacturing lead times. Some specific examples of long-lead items in construction include:

- HVAC systems: Heating, ventilation, and air conditioning systems often have long lead times due to the custom design and fabrication required for each project.

- Elevators: Elevators require significant lead time for design, manufacturing, and installation, and delays in delivery can significantly impact the construction schedule.

- Structural steel: The fabrication and delivery of structural steel components can take several months, making it a long-lead item on many construction projects.

- Large-scale concrete forms: Custom concrete forms for large-scale construction projects may require significant lead time for design, fabrication, and delivery.

- Glass curtain walls: The custom design and manufacturing of glass curtain walls can result in lead times of several months, making it a long-lead item on many construction projects.

Identifying these long-lead items and tracking their delivery is critical to ensuring that construction projects are completed on time and within budget. Project managers must develop a comprehensive procurement strategy that considers the timing, quantity, and specifications of the required items. Effective communication with suppliers and subcontractors is also critical to ensure that long-lead items are ordered and delivered on time.

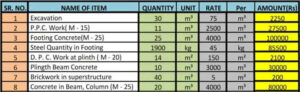

How do you estimate long-lead items in construction?

Estimating long-lead items in construction requires careful consideration of the project schedule and the lead times associated with each item. The first step is to identify potential long-lead items based on the project scope, schedule, and specifications. This can be done by reviewing construction drawings, specifications, and equipment lists, as well as consulting with suppliers and subcontractors.

Once potential long-lead items have been identified, the lead time for each item must be estimated based on historical data, supplier information, and any other relevant factors. This estimate should take into account the time required for design, engineering, manufacturing, and delivery of each item.

To ensure that the estimate is accurate, it is important to communicate with suppliers and subcontractors to confirm lead times and availability of the required items. Project managers should also consider any potential risks or delays associated with the procurement process, such as customs clearance or shipping delays.

What is the difference between long-lead items and critical path items?

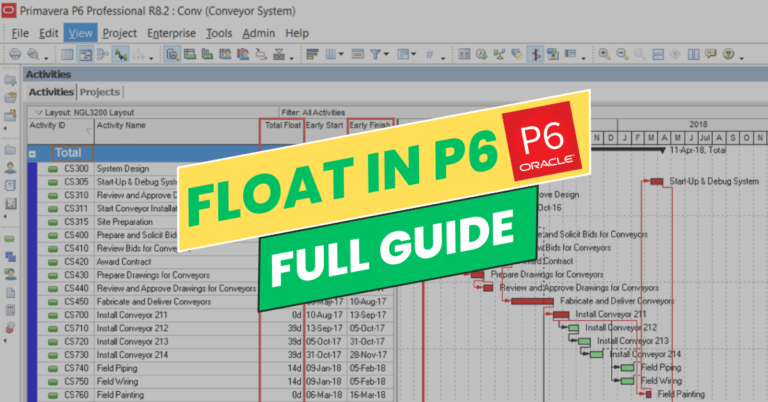

Long-lead items and critical path items are both important components of construction project planning, but they serve different purposes. Long-lead items are components or materials that have a long manufacturing or delivery time and therefore need to be ordered well in advance of when they are required on a construction project. Critical path items, on the other hand, are tasks or activities that are critical to the project schedule and must be completed on time in order for the project to be completed on schedule.

While there may be overlap between long-lead items and critical path items, they serve different functions in project planning. Long-lead items are important to identify and track to ensure that they are delivered on time and do not cause delays in the construction process. Critical path items are important to identify and track to ensure that the project schedule is maintained and that the project is completed on time.

In summary, long-lead items are components or materials that have a long manufacturing or delivery time and need to be ordered well in advance of when they are required on a construction project. They can have a significant impact on the construction schedule if they are not identified and managed properly. Effective management of long-lead items requires a comprehensive procurement strategy, effective communication with suppliers and subcontractors, and careful estimation of lead times.